FUEL

Experts in Advancing Renewable Biofuel Infrastructure Solutions.

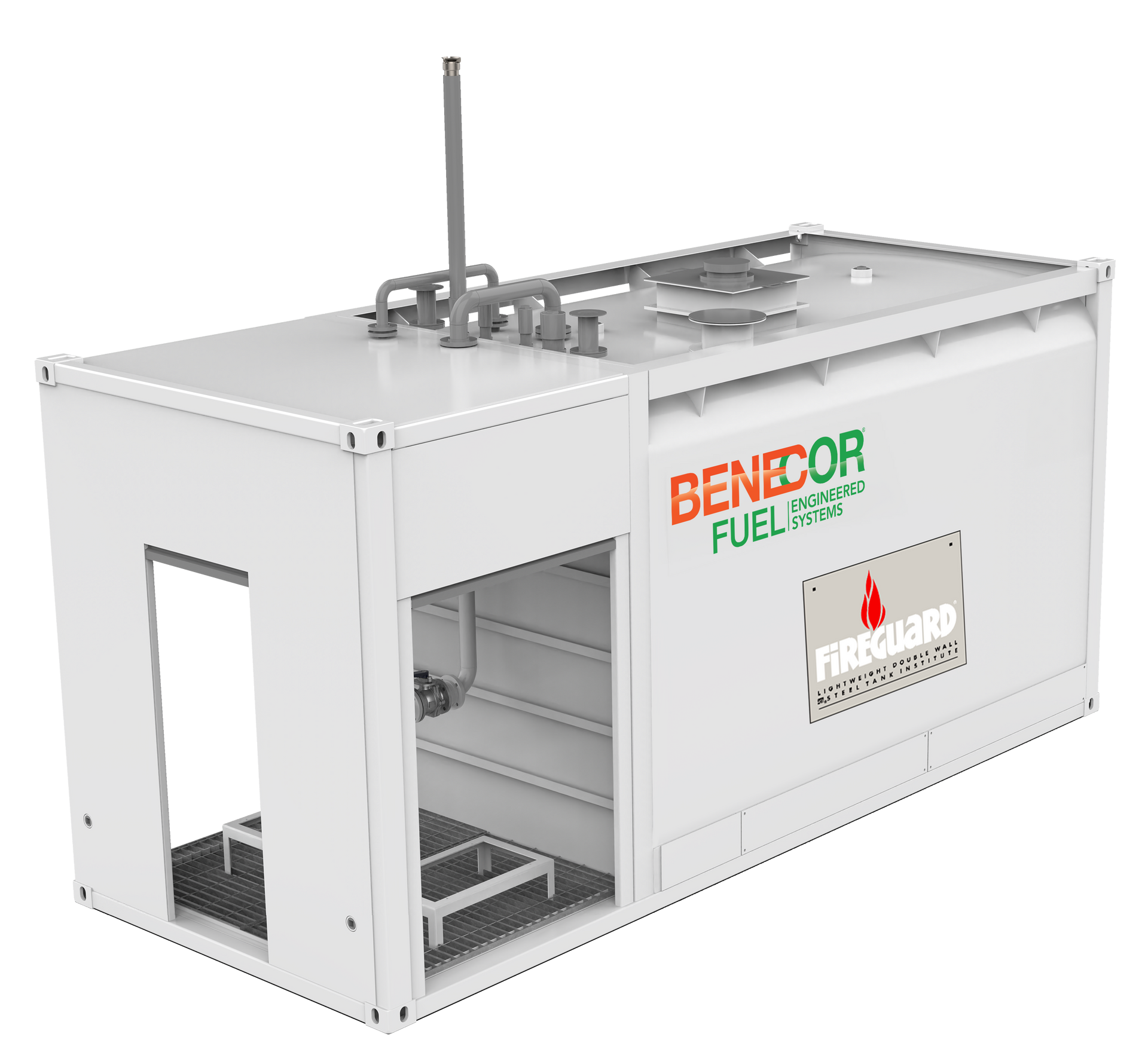

Benecor’s Aboveground Fuel Systems are engineered to deliver high-capacity, secure, and efficient fuel storage—customized to meet the needs of your environment. Our fully customized fuel systems are designed for durability, mobility, and seamless dispensing integration. Whether you're fueling a remote job site or a full-scale industrial operation, we’ve got the right solution.

Below are some of our standard tank offerings, but these are just a starting point that we can use to customize and build a solution for your specific needs.

Turnkey Tanks. Built to Fit Your Operation.

Benecor’s infrastructure solutions are designed with flexibility in mind, enabling seamless integration into both fleet facilities and high-traffic retail fuel stations. The company's emphasis on quality and ease of implementation ensures that these systems are both sustainable and scalable, empowering operators to adopt renewable fuels like biodiesel with minimal disruption.

CONSULTATION

Benecor’s consultation services go beyond standard design assistance. Our team of experts applies decades of hands-on industry experience to analyze your operational needs, environmental conditions, and compliance requirements.

ENGINEERING & DESIGN

We then apply our in-house engineering and design expertise to create tailored fuel system specifications that deliver optimal performance, unmatched reliability, and maximum efficiency—solutions you won’t find in a one-size-fits-all approach.

CONCEPT

As part of our process, we present customers with a detailed 3D concept of the design, allowing them to visualize the final system before production begins.

Systems integration & Manufacturing

With advanced fabrication, custom engineering, and industry expertise, Benecor builds equipment that ensures durability, reliability, and compliance in demanding environments.

DELIVERY

Benecor’s logistics team specializes in transporting large, heavy equipment, ensuring our tanks and systems arrive safely, on schedule, and ready for installation.

INSTALLATION & COMMISSIONING

Benecor’s turnkey project management services guide your system from design through installation and commissioning, ensuring a smooth, efficient, and fully operational solution.

2200 - 3600 Gallon Double Wall Fuel Tanks

Compact. Mobile. Site-Ready.

Benecor’s 2200-3600 tanks are the perfect solution for job sites, emergency backup, or operations with space limitations. Designed for mobility and quick setup, this compact tank provides secure storage and dispensing in a small, efficient footprint.

- Ideal for temporary or mobile fueling setups

- Quick deployment and easy transport

- Secure, lockable access with heavy-duty construction

- Compatible with diesel, gasoline, and DEF (when specified)

5700 - 8300 Double Wall Fuel Tanks

Mid-Size Capacity. Maximum Flexibility.

The 5700 - 8300 Fuel Tank Systems strike the perfect balance between capacity and footprint. Designed for medium-to-large operations, it offers robust storage and integrated dispensing options—all while remaining easy to transport and install.

- Mid-range capacity for growing fuel demands

- Configurable with multiple pumps, hose reels, and meters

- Fully engineered for turnkey fueling applications

- Built to withstand rugged environments and extended outdoor use

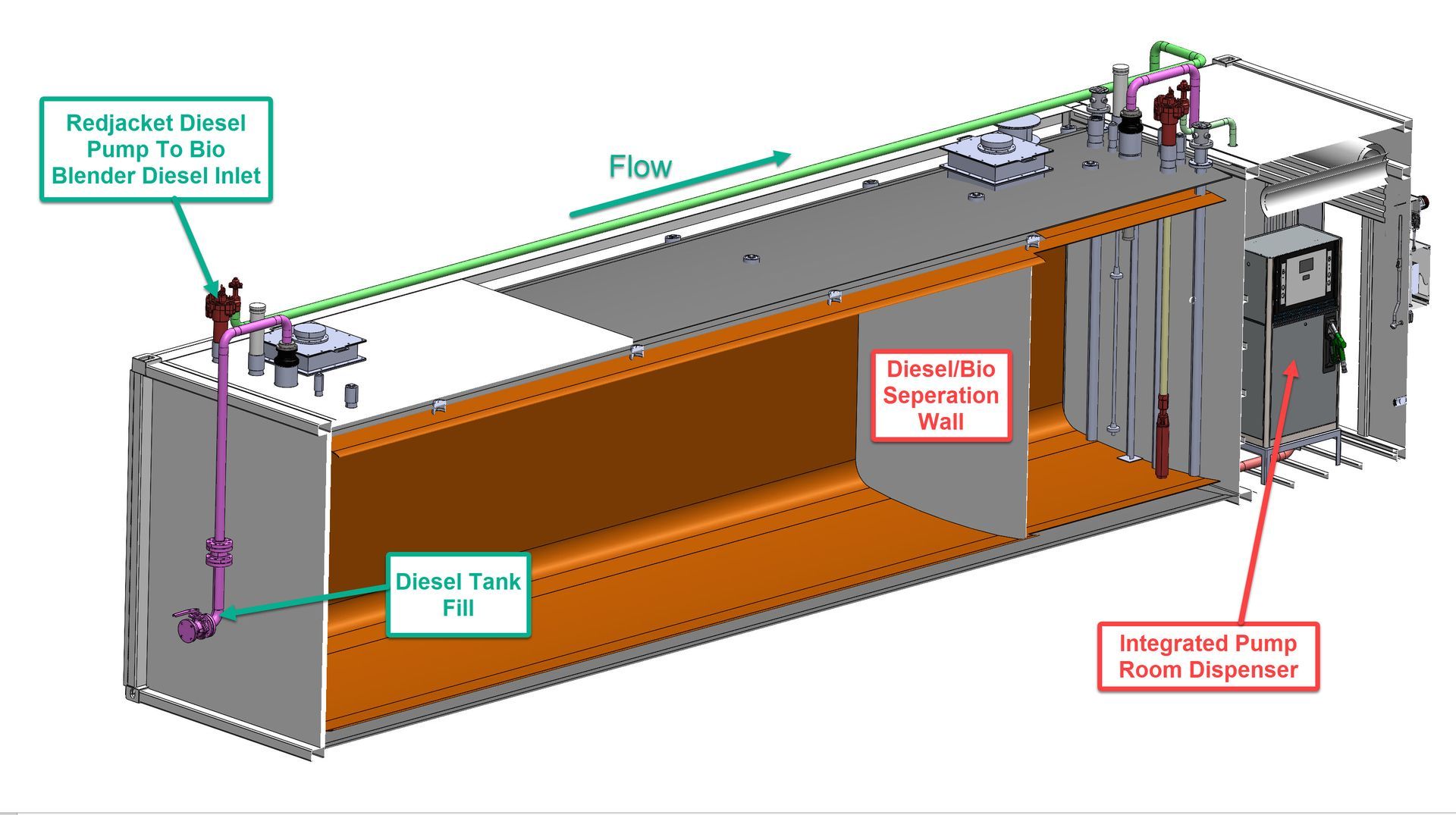

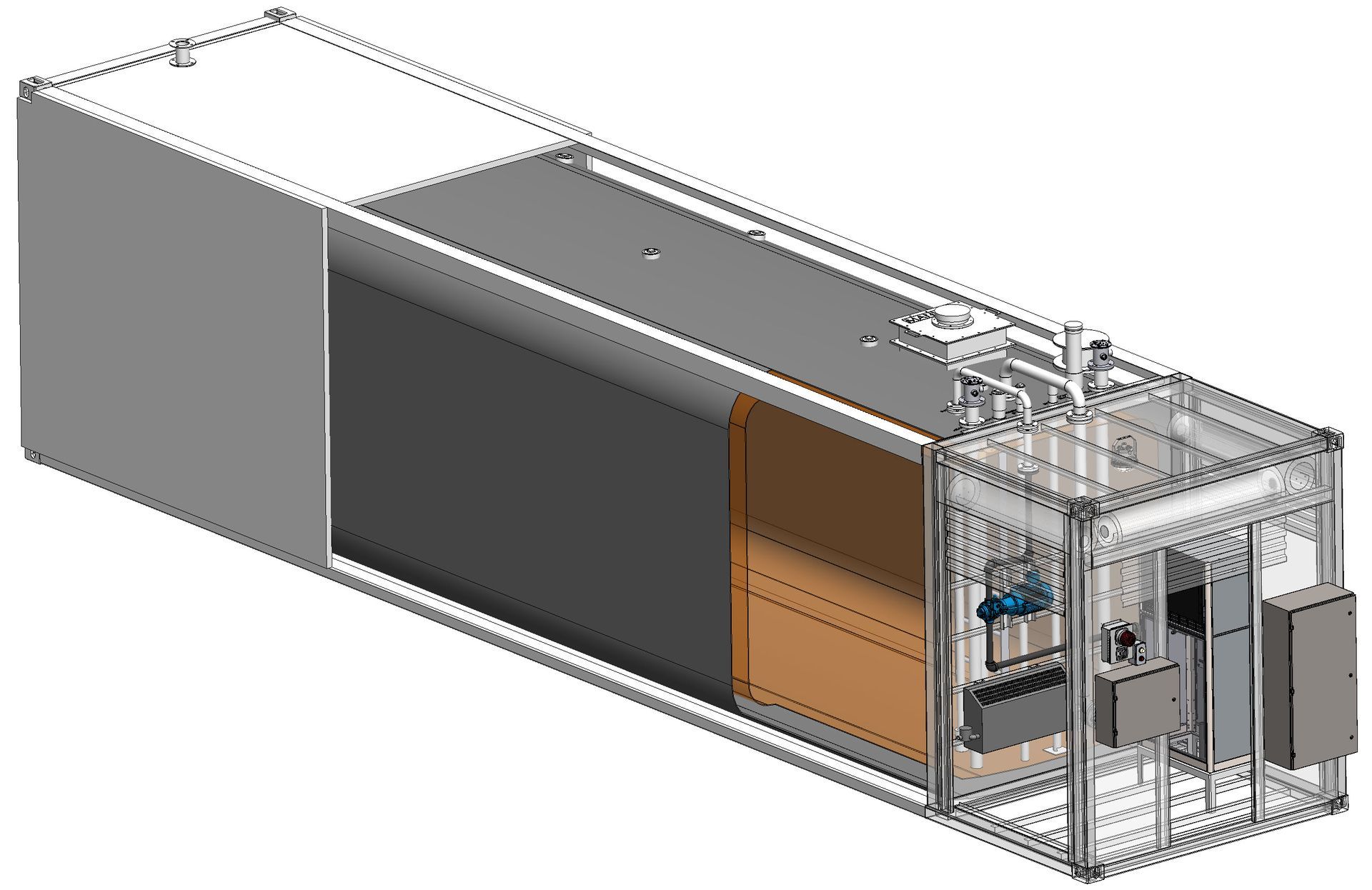

14700 - 17100 Gallon Double Wall Fuel Tanks

High-Capacity. Industrial Strength.

Benecor’s 14700 - 17100 Gallon Fuel Tanks are the workhorse of our fuel system lineup. Engineered for large-scale operations, this high-volume tank is ideal for fleet fueling, logistics hubs, or industrial fueling infrastructure where uptime and storage capacity are critical.

- Largest fuel storage in our standard lineup

- Integrated dispensing systems and power options

- Heavy-duty, weather-resistant construction

- Can be customized for multi-fluid or DEF combo systems

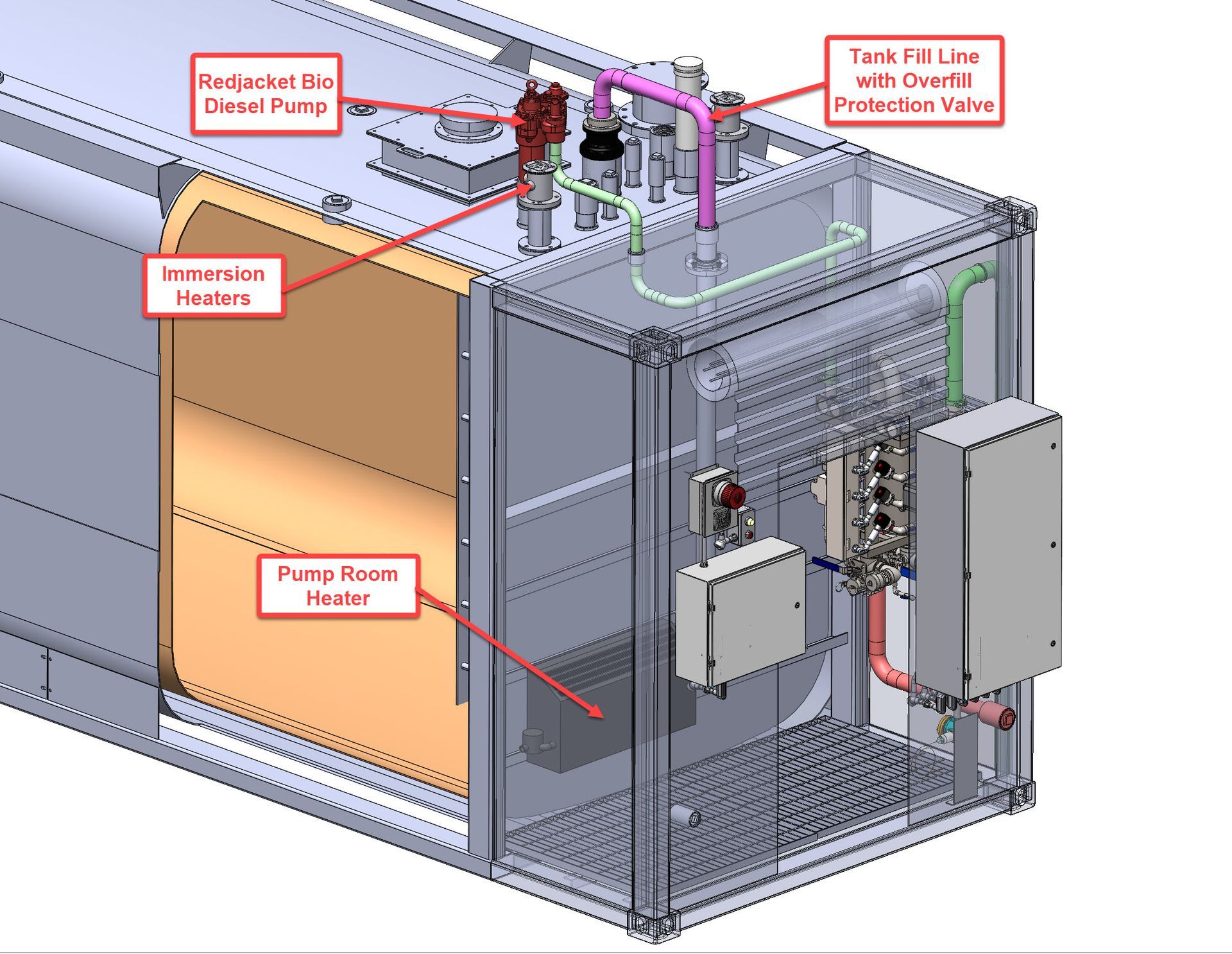

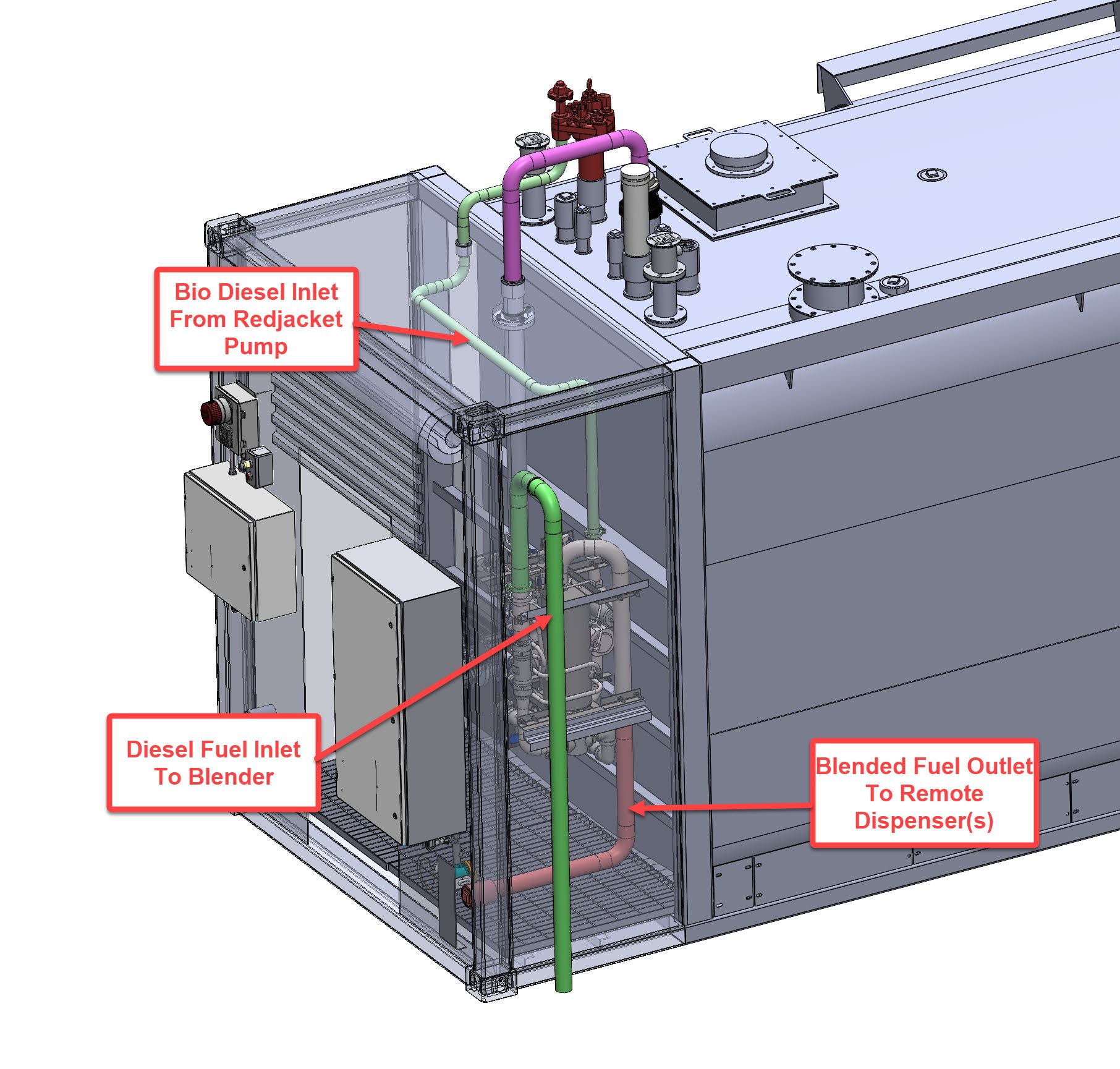

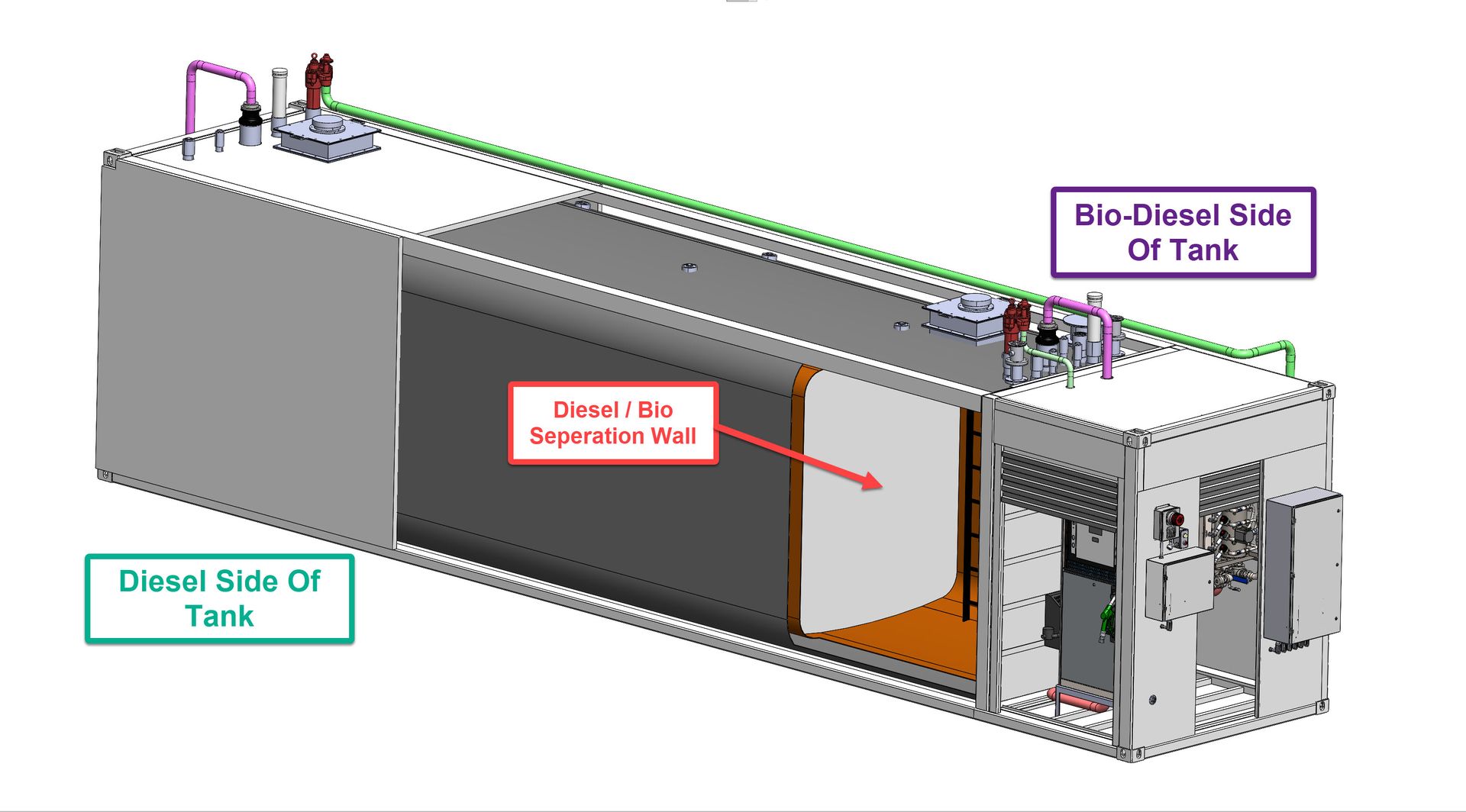

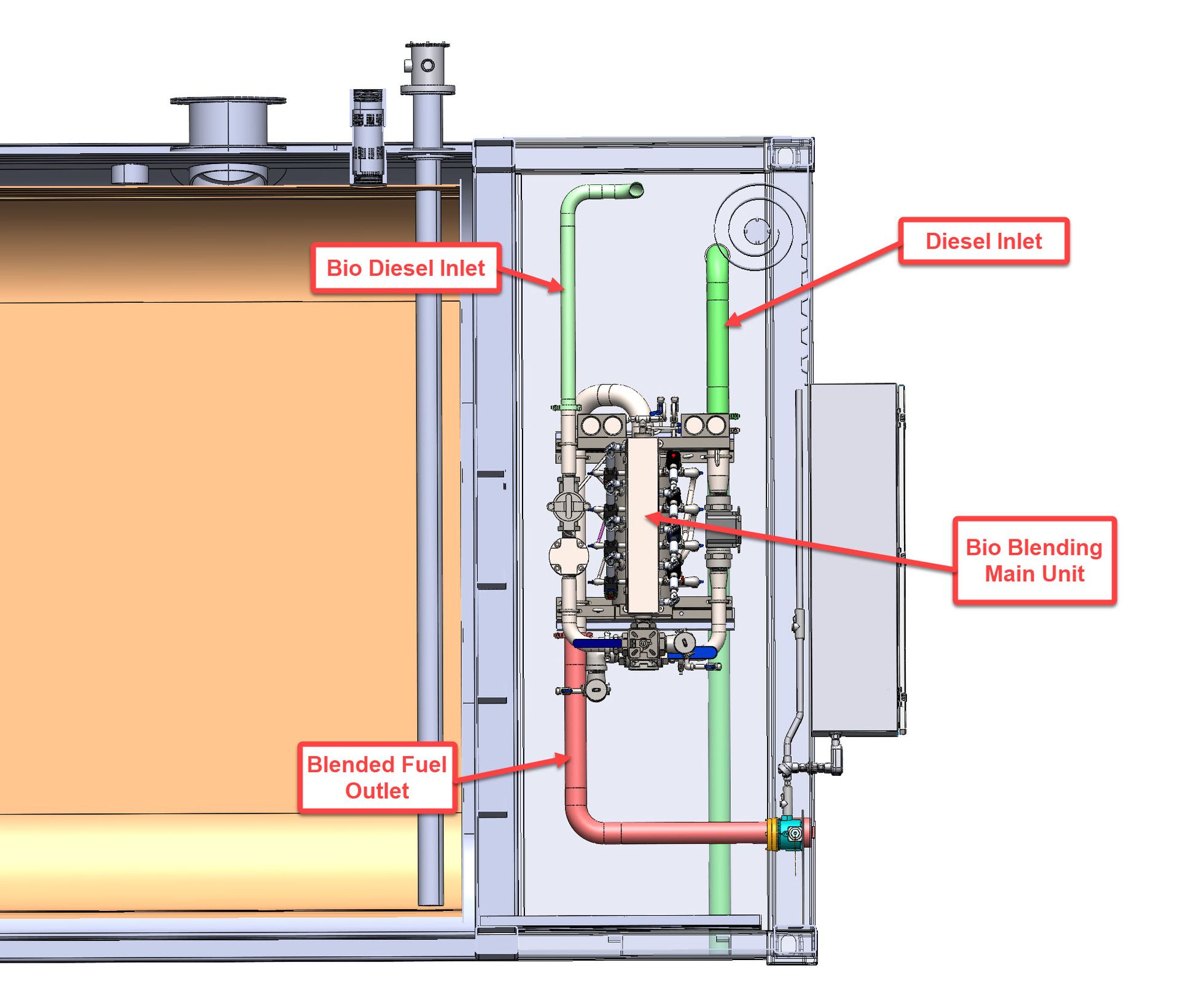

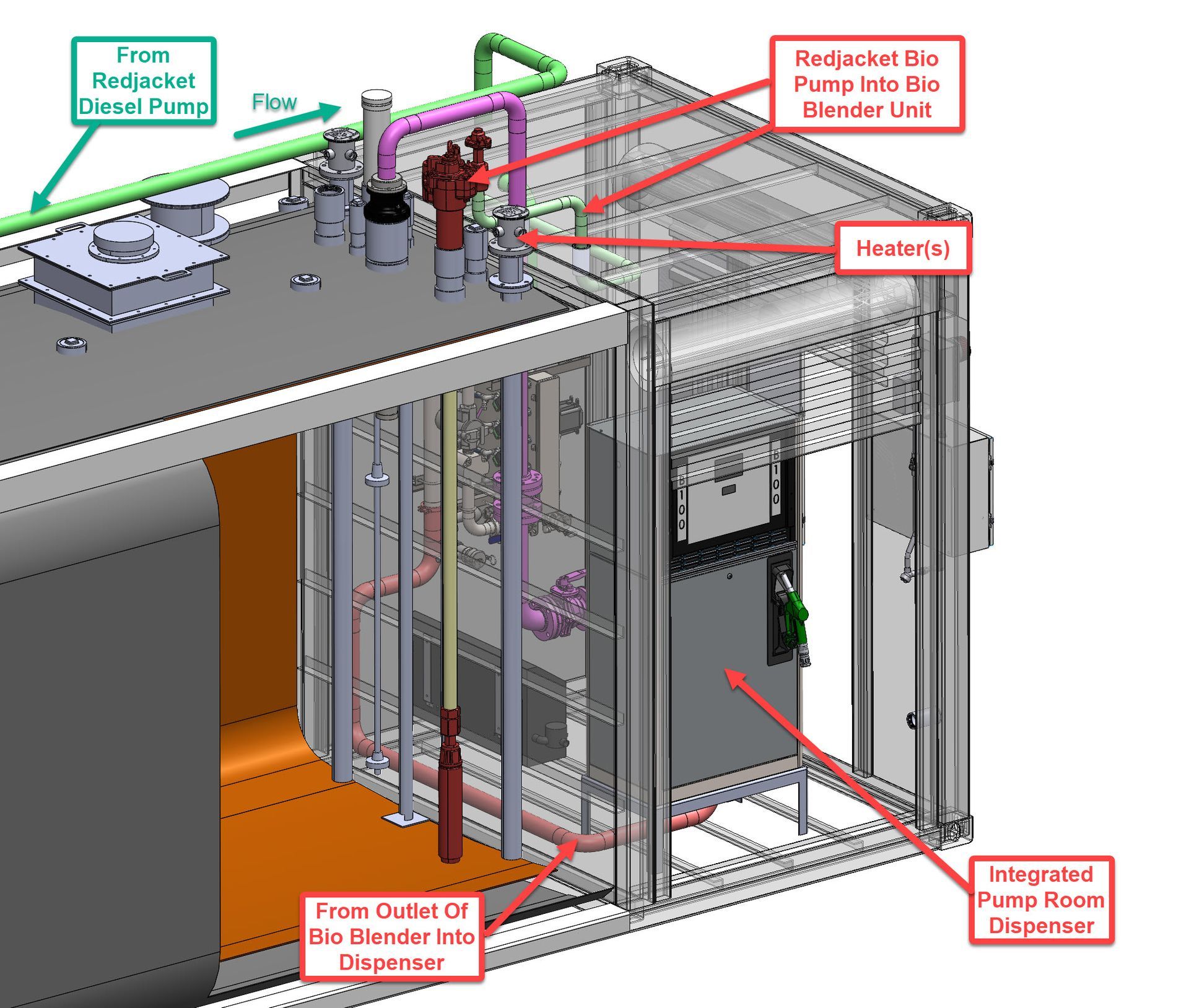

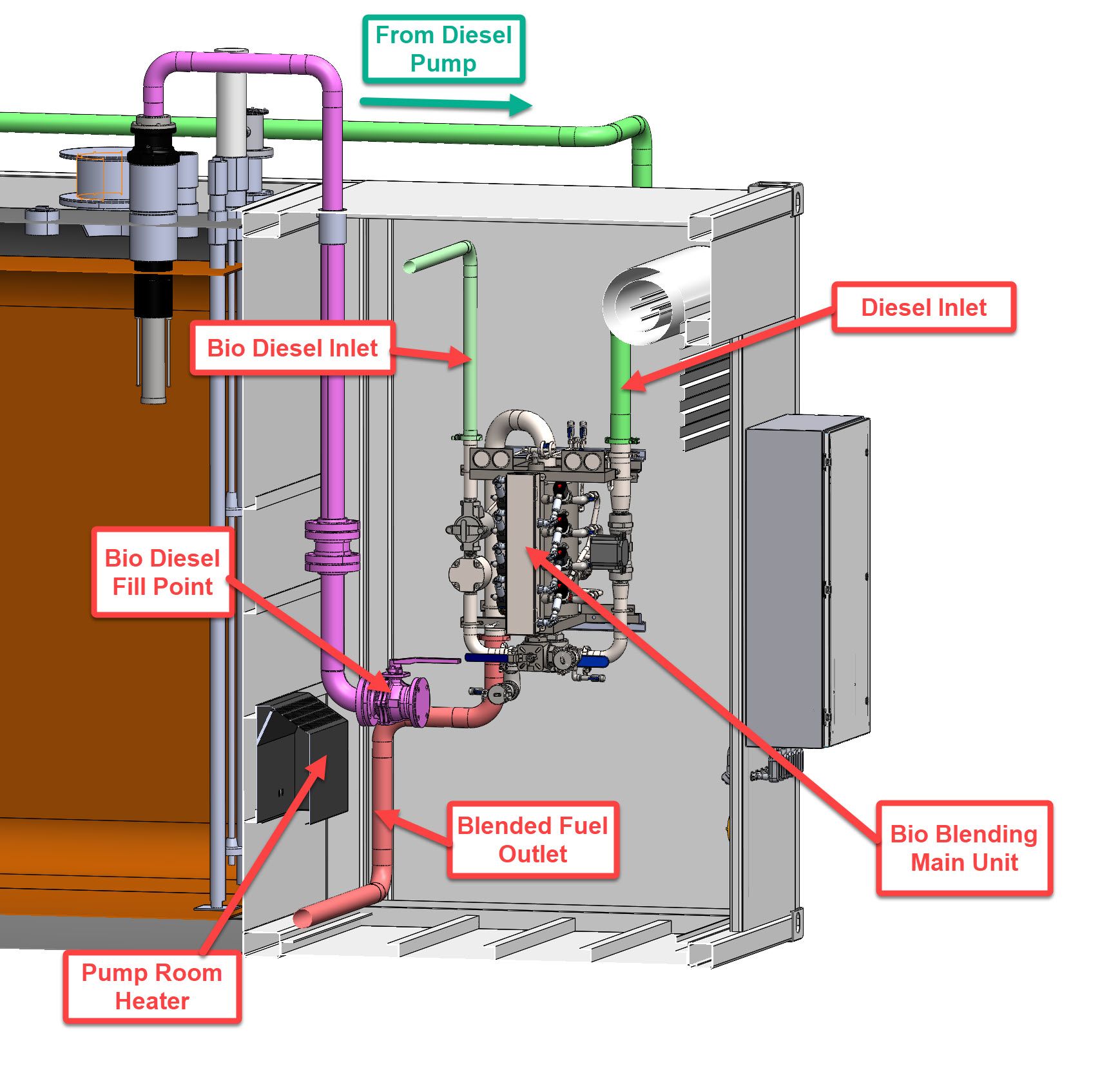

BIO BLENDER SYSTEM

System Features

Manage blend ratios on the fly without committing to batch blending. The BBS is a versatile in-line solution that delivers precise blending of biodiesel within retail locations.

- Tight tolerances over desired blend ratio are ensured with precision meters and controller logic

- Automatic adjustments made by Blend Control Valves to maintain desired blend ratio within +/- 0.05% of target

- No stratification - static blender ensures product consistency

- Leverages commonly used retail equipment for easy access to spares, trained technicians

- Hydrostatically sealed and stainless-steel construction may be installed aboveground or underground

How it Works

1

The tls-450plus atg

Receives the hook signal from the dispenser and turns on the diesel Red Jacket® Submersible Turbine Pump (STP) to start the flow of product

2

the diEsel meter

On the BBS continuously monitors the flow of diesel through the blender

3

the blend control valves

Open to inject the correct amount of B100 into the blender

4

The static blender

Mixes products within, resulting in a uniform blend that is sent to the dispenser island

5

the b100 meter

Is continuously monitored to ensure the target blend ratio is achieved

6

the blending transaction data

Is updated live in the BBS controller, where it can be accessed via Application Programming Interface (API) or network connection

Flow Rates

| Desired Site Throughput (B20) | Diesel STP | Approximate Diesel STP Flow | Biofuel STP |

|---|---|---|---|

| 100 GPM | 4" - 1.5 HP | 80 GPM | 4" - 1.5 HP X3 |

| 100 GPM | 4" - 2 HP Low Pressure | 80 GPM | 4" - 1.5 HP X3 |

| 100 GPM | 4" - 2 HP | 85 GPM | 4" - 1.5 HP X3 |

| 150 GPM | 4" - 2 + 1.5 HP Manifolded | 160 GPM | 4" - 1.5 HP X3 |

| 200 GPM | 4" - 2 + 2 HP Manifolded | 170 GPM | 4" - 1.5 HP X3 |

| 200 GPM | 6" - 3 HP Maxxum | 170 GPM | 4" - 1.5 HP X3 |

| 250 GPM | 6" - 5 HP Maxxum | 260 GPM | 4" - 1.5 HP X3 |

| 300 GPM | 6" - 5 HP Maxxum | 260 GPM | 4" - 1.5 HP X3 |

| 350 GPM | 6" - 2 + 3 HP Maxxum Manifolded | 350 GPM | 4" - 2 + 1.5 HP X3 Manifolded |

Benefits

Ease of Installation

The installation of an aboveground fuel tank is easier and faster in comparison to an underground fuel tank.

Cost of Installation

The cost of installation is significantly less than an underground fuel tank. Without the need to excavate to install the tank and the cost of UST insurance and compliance requirements the site will save cost.

Maintenance and Inspections

When you install an AST fuel tank your maintenance and inspection cost are much lower since everything is visible.

Compact Footprint

Our FuelTainer is compact, large capacity, and self-contained.

Flexibility in Blend Ratio

With the use of the Bio Blending system the site can adjust the blend ratio from 2% to 45%. (when applicable)

Why Choose BENECOR®?

At BENECOR®, our team of experts are dedicated to delivering optimal, cost-effective solutions with unmatched product knowledge and customer service.

Our Renewable Fuels Engineered Systems provide ready-to-use dispensing and storage solutions for fleet and retail settings. From planning to installation and commissioning, we offer full design, engineering, and installation support for systems of all sizes.

1

EFFICIENCY:

Simple setup—just connect power and fill with fuel.

2

FLEXIBILITY:

Easy to relocate and adapt to changing business needs.

3

SAFETY & SUSTAINABILITY:

Higher leak mitigation and integrity reduce costs, save time, and ensure environmental safety.

4

SUPERIOR QUALITY:

Factory-built units offer better control, reduced installation challenges, and lower costs compared to traditional on-site systems.

5

RELIABILITY & ADAPTABILITY

Adaptable to multiple renewable fuels, providing a future-proof energy storage solution that meets your long-term sustainability goals.

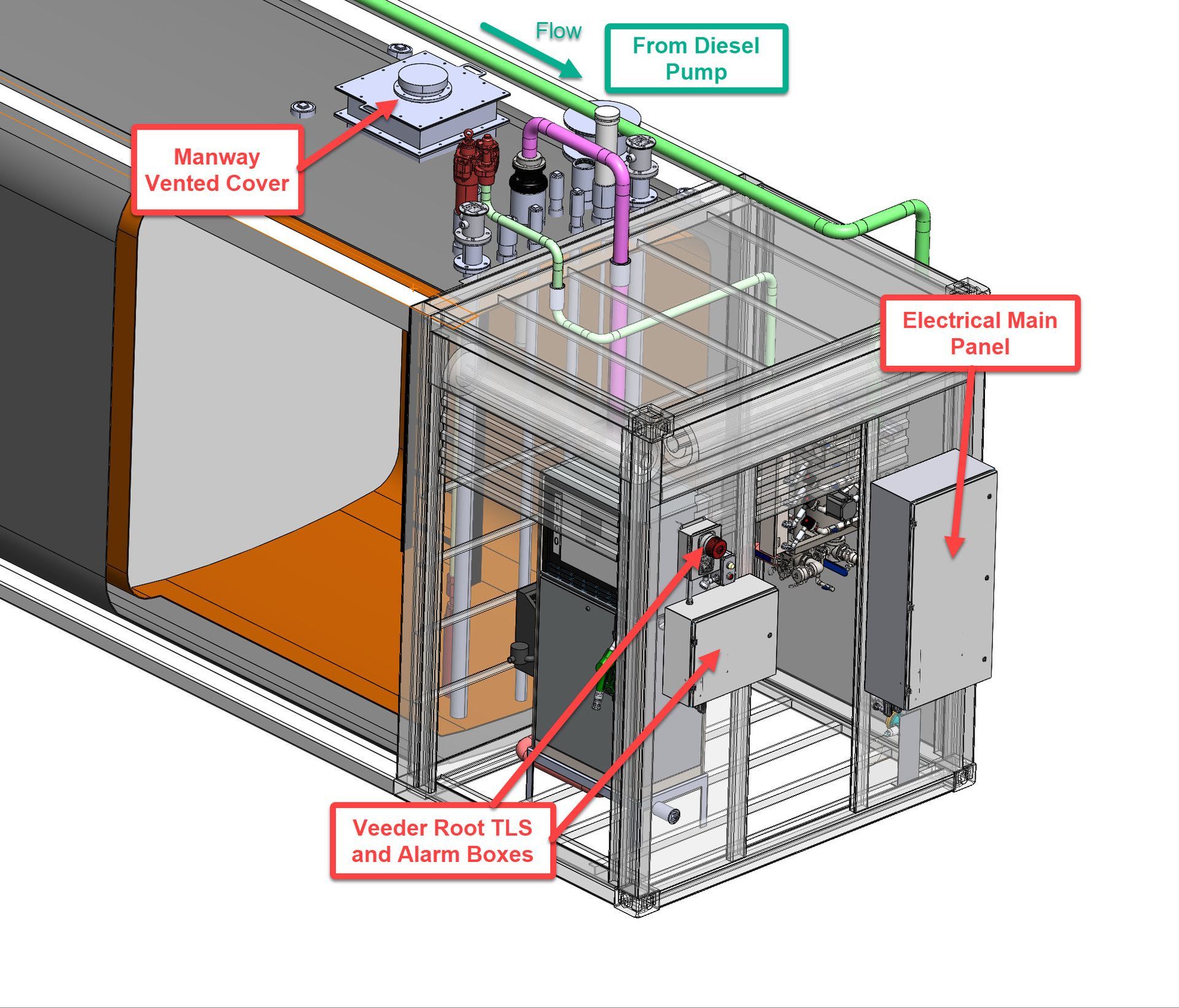

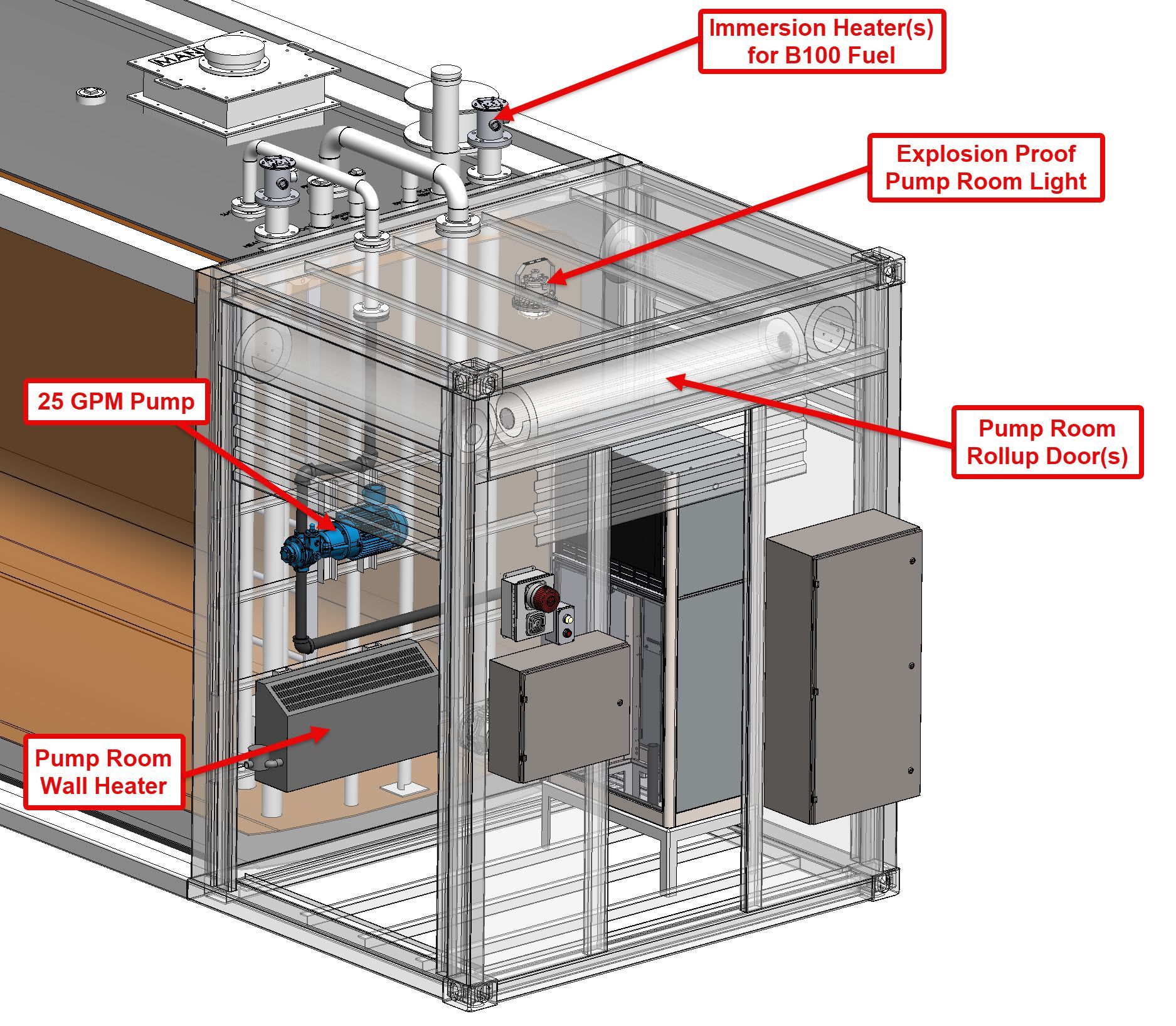

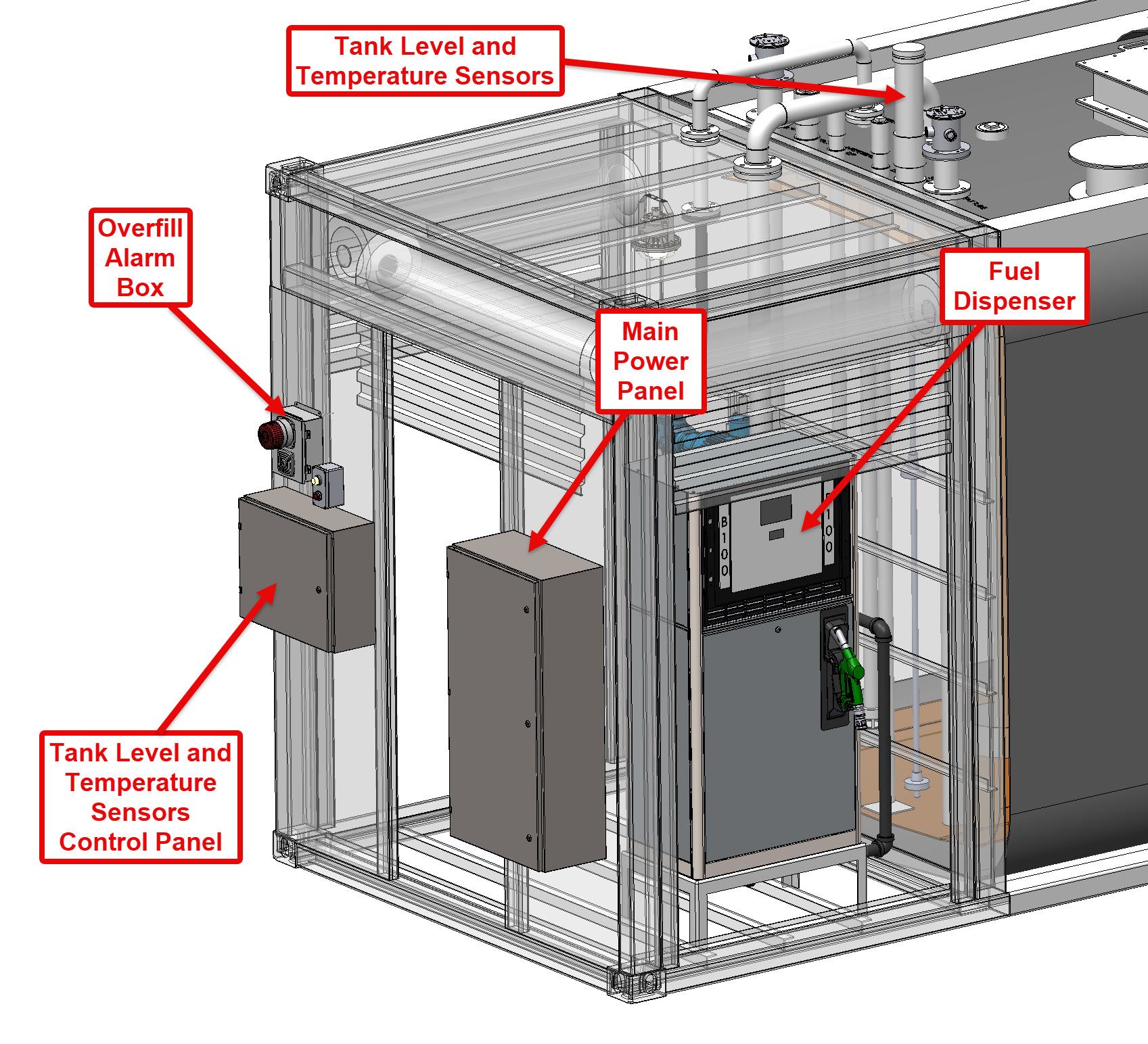

Featured:

40 ft with pump room

COMPLETE SYSTEMS:

BENECOR® systems are designed, engineered, and manufactured in the factory, not in the field, with everything you need—tanks, plumbing, pumps, dispensers, electric panel, nozzles, hoses, fuel management, monitoring, and more—all seamlessly integrated and ready for use.

EXAMPLES: