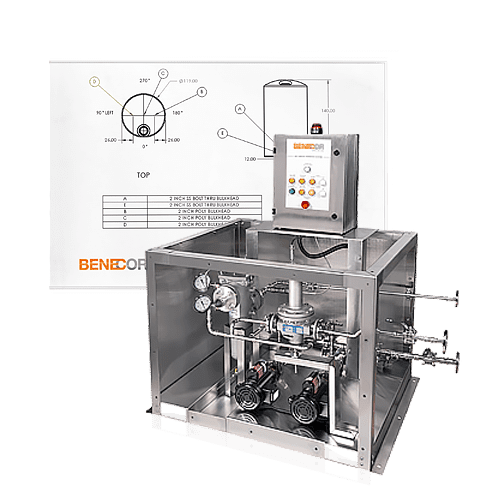

BENECOR offers the latest, most advanced “Plug & Play” Inline Blending & Dissolving Technology to produce the highest quality of DEF.

- Inline Refractometer Provides Constant Monitoring of the Concentration.

- DRO WTS is easy to operate 24/7 – no supervision required.

- Siemens PLC allows to supervise and administrate at distance, the production of DEF and functionality of the Machine.

- Made with ISO 22241 compatible materials using the most reliable equipment.

- DRO WTS meets ISO 22241 standard water requirements.

ENGINEERED FOR CUSTOMIZATION

The BENECOR Inline Blending Systems allow you to produce DEF Solution with concentrations up to 50%. 1.050, 2.375 & 4.750 Gallons of DEF can be produced per hour.

HEAT PLATE EXCHANGER

To reach high temperature of demineralized water, BENECOR Inline Blending Systems contain a heat plate exchanger in order to reach required temperature for inline blending (at least 86°F / 30°C). The user needs to supply hot water or steam to the heat plate exchanger to make it function.

DEF DEBAGGING UNIT

Hopper with capacity of 70.6ft3, 141.2 ft3 or 247.2ft3 (2m3, 4m3 or 7m3) contains minimum loading sensors and alarm. Hopper has built in top grid which serves as sieve with mesh size 0.39in x 0.39in (10mm x 10mm). Urea crusher (lump breaker) can be integrated in the hopper.

SCREW CONVEYORS

Screw conveyors are fully integrated in the functionality of the BENECOR Inline Blending & Dissolving Systems.

SPACE-SAVING

The total BENECOR Inline Blending Systems fits in only one 40ft container (without DEF & water storage tanks).

DOUBLE REVERSE OSMOSIS WATER TREATMENT SYSTEM (DRO WTS)

Can produce 264.1G/h, 528.3G/h or 1320.8G/h (1m3/h, 2m3/h or 5m3/h) of demineralized water depending on the size of the machine.

REDUCE OPERATOR INVOLVEMENT

STANDARDS / APPROVALS

OPTIONAL FEATURES INCLUDE

Three Blending Capacities: 1.050G/h, 2.375G/h & 4.750G/h (4,000L/h, 9,000L/h & 18,000L/h)